SHOWCASE

|

|

|

|

|

|

|

January 2021: Dust Monitoring / Broken Bag Detection |

Dust Monitors with Hazardous Location Approval |

Elburn, IL - The DustAlarmTM ES and DustTrendTM ES, Monitor Technologies’ trusted series of broken bag detectors and dust emission trend monitoring systems, are now available with hazardous location approvals. Plus, they have intrinsically safe probes for ultimate hazardous location protection, These monitors provide excellent repeatability that is not affected by variations in relative humidity, process temperature or pressure. They use proven AC Triboelectric technology with advanced algorithms to filter out noise and provide the most accurate dust measurement. The monitors have an easy auto set-up function that is activated by pressing a button to automatically configure parameters / alarms. They contain externally viewable bi-color LED indication on ordinary location units. These units are ideal for monitoring the level of dust emission in dust collection system exhausts, etc. They help anywhere it is critical to safety, maintenance, equipment operation, plant efficiency (energy-savings), employee welfare and the environment. The monitors can be connected with the free DustConfigTM software to set custom alarm points, view live activity within the duct, or review data history for up to a 24-hour period.

The DustTrendTM ES dust emission trend monitor adds the ability to provide continuous trend measurements that allows a plant operator to identify changes in dust emission levels and optimize the facility's filtration / dust collection system. It also provides 4-20mA analog output and / or enhanced Modbus(RS-485) output.

For more information please visit www.monitortech.com, e-mail monitor@monitortech.com or contact us at 1-800-601-6165 or 1-630-365-9403.

About Monitor

Monitor Technologies LLC is a dependable leading manufacturer & supplier of level measurement instrumentation, solids flow indicators, inline moisture measurement, particle emission monitors and aeration devices for the worldwide powder and bulk solids markets. The experience and market knowledge gained over 60 years of business has earned Monitor a reputation for providing high quality product solutions backed by extensive application support and trusted customer service. Monitor is located in Elburn, Illinois, US and is ISO 9001 registered. For more information please refer to www.monitortech.com or contact Chris Otte of Monitor Technologies at monitor@monitortech.com or 1-800-766-6486 (630-365-9403).

|

|

---------------------------------------------------------------

|

January 2019: Inventory Management |

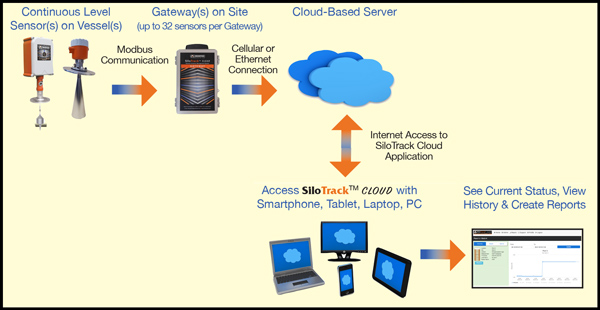

SiloTrack(TM) CLOUD Remote Inventory Management System

|

Elburn, IL - Monitor Technologies is proud to announce the SiloTrack(TM) Cloud remote inventory management system. A web-based application that allows users to monitor current vessel levels, receive notifications, access/create reports and more at any location, any time using any device with an Internet connection. Manage one silo or various locations with multople storage vessels. Securely view distance, level, volume, weight, percentage and ullages (empty space) for silos. It truly provides an intuitive, flexible and powerful interface for Monitor Technologies continuous level sensors to optimize inventory management. For more information please visit www.monitortech.com, e-mail monitor@monitortech.com or contact us at 1-630-365-9403.

Product Webpage: https://www.monitortech.com/silotrack-cloud.shtml

About Monitor

Monitor Technologies, LLC provides practical solutions

for level measurement instrumentation, solids flow

indicators, moisture measurement, particle emission monitors and bin aeration

devices relating to the storage and processing of powders,

bulk solids and some liquids. For more details on Monitor's

product offerings please visit www.monitortech.com

or call 1-630-365-9403. |

|

---------------------------------------------------------------

March 2018: Dust Monitoring / Broken Bag Detection |

DustAlarm® ES and DustTrend(TM)

ES

Latest Generation of Dust Monitors

|

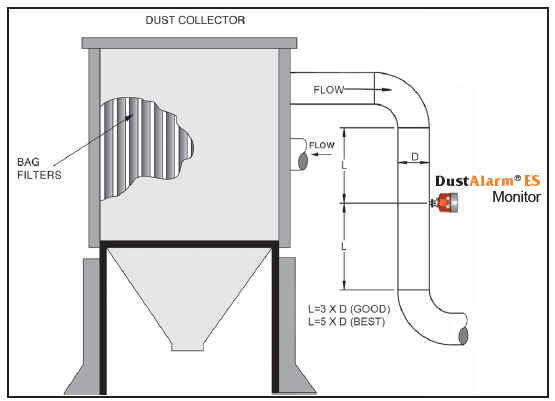

Elburn, IL - Monitor Technologies is proud to introduce the DustAlarm® ES and DustTrend(TM) ES, Monitor’s next generation of broken bag detection and dust emission trend monitoring systems.

Both the DustAlarm ES and DustTrend ES have an easy auto set-up function that is activated by pressing a button to automatically configure parameters / alarms. These monitors provide excellent repeatability that is not affected by variations in relative humidity, process temperature or pressure. They use proven AC Triboelectric technology with advanced algorithms to filter out noise and provide the most accurate dust measurement. They are ideal for broken bag detection / leaking filter detection in the exhaust ducts of baghouses of various sizes, cartridge collectors, cyclones, and any other dust collector containing filters which may break or wear out. The monitors can be connected with the free DustConfig(TM) software to set custom alarm points, view live activity within the duct, or review data history for up to a 24-hour period.

The DustAlarm ES is an economical dust monitor that provides an alternative to opacity detection. The DustAlarm ES contains relay output or digital RS-485(Modbus) connection as an alternative to relay output and/or for connecting multiple sensors to one control system.

The DustTrend ES dust emission trend monitor adds the ability to provide continuous trend measurements that allow plant operators to identify changes in dust emission levels and optimize the facility's filtration systems. It also provides 4-20mA analog output and/or enhanced Modbus(RS-485) output.

Additional features for both units include two conduit openings, bi-color LED indication, die-cast aluminum housing and USB mini-B port for communication with DustConfig software.

For more product details please visit www.monitortech.com,

e-mail monitor@monitortech.com or contact us at 1-630-365-9403.

Product Webpage: https://www.monitortech.com/product_pe.shtml

About Monitor

Monitor Technologies, LLC provides practical solutions

for level measurement instrumentation, solids flow

indicators, moisture measurement, particle emission monitors and bin aeration

devices relating to the storage and processing of powders,

bulk solids and some liquids. For more details on Monitor's

product offerings please visit www.monitortech.com

or call 1-630-365-9403. |

|

---------------------------------------------------------------

February 2018: Vibratory Level Sensors |

DuraVibe(TM) Model PZP and Model VibraRod Durable and Versatile Vibratory Style Level Indicators

|

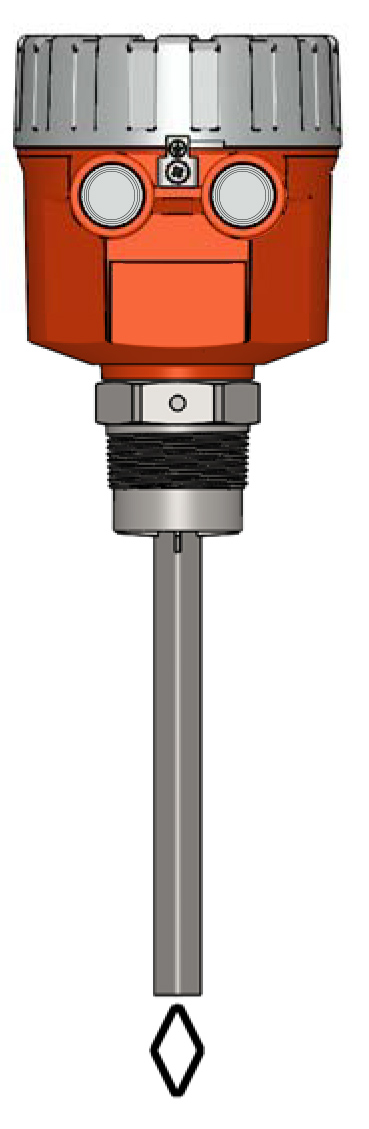

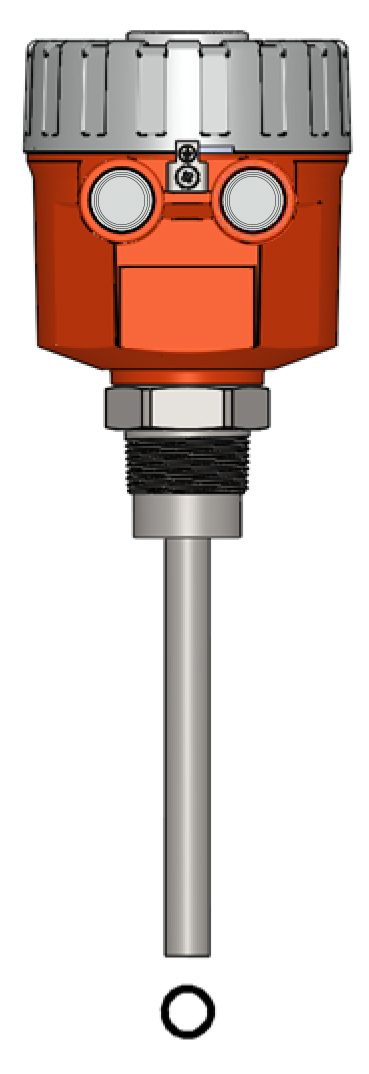

Elburn, IL - Monitor Technologies is proud to introduce the DuraVibe(TM) Series, Monitor’s newest generation of durable and versatile vibratory style level sensors for powders and bulk solids. The DuraVibe Series consists of the Model PZP and Model VibraRodTM. Both models have been designed to offer the ultimate hazardous location protection with intrinsically-safe probes. The DuraVibe sensors do not require calibration and are unaffected by varying material compositions, like temperature, moisture, etc. In addition, DuraVibe Series includes an external status LED (on Ord. Loc. units) and a fail-safe signal in case of power loss. Both models offer single-probe designs that prevent material build-up that causes false signaling. The Model VibraRod is a sturdy and reliable level indicator for a variety of applications, yet is an economical vibratory level solution. The Model PZP has a diamond-shape probe that provides superior durability with industry-leading probe strength and excellent versatility to detect very light to heavy materials. The Model PZP offers a variety of configurations including pipe extension, cable extension & high-temperature options.

For more product details please visit www.monitortech.com,

e-mail monitor@monitortech.com or contact us at 1-630-365-9403.

Product Webpage: https://www.monitortech.com/product_point.shtml#vibe

About Monitor

Monitor Technologies, LLC provides practical solutions

for level measurement instrumentation, solids flow

indicators, moisture measurement, particle emission monitors and bin aeration

devices relating to the storage and processing of powders,

bulk solids and some liquids. For more details on Monitor's

product offerings please visit www.monitortech.com

or call 1-630-365-9403. |

|

|

|

|

|

|

|

|

QuantiMassTM

Mass Flow Measurement Systems |

The QuantiMass in-line mass flow sensor measures the flow of quantities in pneumatic conveying & free-falling processes. The sensor is based on the latest Microwave Doppler Effect technology and provides fast, in-line / on-line measuring without the use of weight scales.

The sturdy, non-intrusive design of the sensor minimizes maintenance. In addition, the compact size of the sensor makes for easy installation into existing processes. Suitable for powders, dust, pellets, and granular up to 0.75 inch (2cm).

Versions:

Ultra Series-Includes controller

PRO Series-Includes transmitter

A practical application for the QuantiMass would be to monitor material flow rates to verify blending mixture ratios.

Principle of Operation:

The QuantiMass Mass Flow Measurement Sensor / Meter is designed with the latest microwave technology and is used to continuously quantify the flow of powders & solids being conveyed in metallic pipes. The QuantiMass is based on technology that has been developed and proven over several years. The measurement process of the sensor is centered on the Doppler effect. The mass flow-rate is determined by evaluating the frequency and amplitude changes during the measurement process. Particles at rest, such as deposits, do not influence the measurement. All powders, dust, pellets and granules can be measured reproducibly, up to the size of 0.75 inch (2cm). The QuantiMass sensor is suitable for continuous in-line / on-line measurements in pneumatic conveying or in free-fall pipelines.

Click

here for more information on the QuantiMass

or

contact Monitor Technologies LLC at

Tel.: 800-601-6319 in the USA and

Tel.: 630-365-9403

worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|