Products & Solutions:

Monitor Technologies provides a wide range of solutions for level indicators and controls, continuous level sensors, inventory management, solids flow monitoring / metering, in-line moisture measurement, dust monitoring / broken bag detection and bin aeration for the storage and processing of powders & bulk solids.

For over 60 years we have strived to offer high quality products, extensive application support and trusted customer support.

Markets Served:

We offer application solutions for a large variety of industries / target materials including (but not limited to): plastics, cement and aggregates, fly ash, coal / power plants, mining, biofuels, feed and grain, food packaging, ingredients, baking & snacks, pet food, pulp & paper, pharmaceuticals, chemicals, and more powders and bulk solids. Also some slurry and liquid applications.

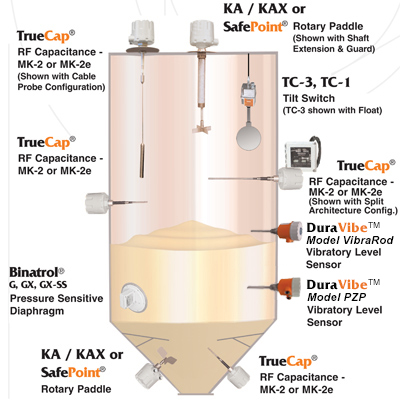

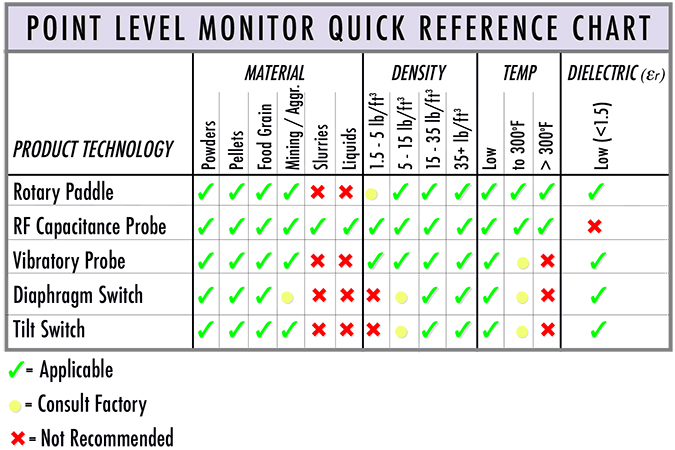

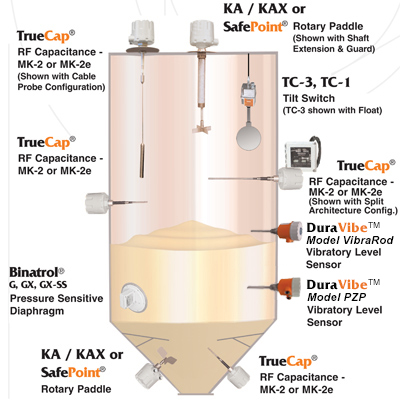

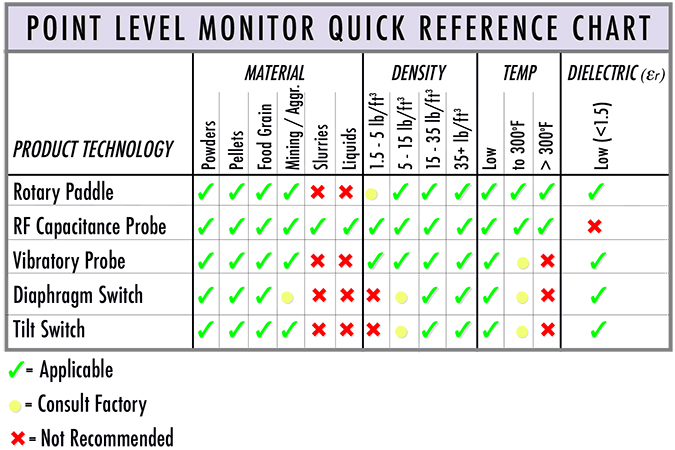

Point Level Sensors:

Need some more information?...Click on the button.

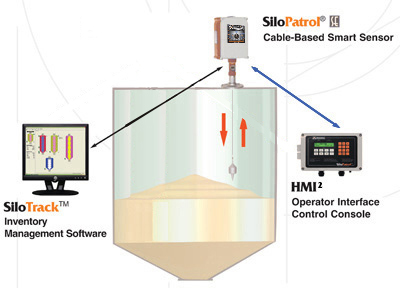

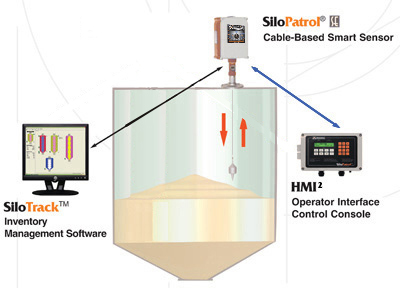

Continuous Level Sensors:

SiloTrack Cloud

Remote Inventory Management Web-Based Application |

|

| CONTINUOUS LEVEL QUICK REFERENCE CHART |

| Plumb Bob Style |

Non-Contact Radar |

> Measuring range

up to 150 ft (45.7 m) in height.

> Measurements taken at continuous intervals or on-demand.

> Not affected by material composition, including dielectric.

> Electromechanical design.

|

> Measuring range

up to 100 ft (30 m) in height for solids and liquids

> Continuous, instantaneous (real-time) measurements.

> Non-Contact ...nothing to "touch" your process

> Material's dielectric needs to be considered.

> Electronic...No moving parts.

|

( click here )

Complete Product Offerings: