| |

PRODUCTS

|

|

|

|

|

|

|

|

|

|

|

|

The

models PAC-30U and PDC-30 proximity bin level switches are

solid state point level devices used to detect the absence

or presence of bulk solids. The compact configuration makes

this product ideal for tight spaces or low cost level detection.

As material comes in contact with, or in close proximity to,

the PAC-30U or PDC-30, an internal solid state switch is activated.

The PAC-30U is AC operated (20-265 VAC) and is universal in

that it is switch selectable for either normally open or normally

closed operation. The PDC-30 is DC operated (10-40 VDC) and

is available in either PNP or NPN configuration, each of

which can be wired in either a normally open or normally

closed operation mode.

|

|

Principle of Operation |

|

The

PAC-30U and PDC-30 are RF capacitance-type level controls,

which operate by detecting the electrical effect of the surrounding

material such as air, plastic pellets or powders. A radio

frequency is applied to the proximity switch sensing region

and is continually analyzed to determine the influence of

the surrounding environment. Since all materials have dielectric

constants and conductance values that are different from

that of air, the resultant impedance seen by the radio frequency

changes whenever material approaches or contacts the sensing

region. This influence is measured within the circuitry and

compared with the reference point set by the sensitivity

adjustment, which determines how much influence must be present

before the output changes.

|

|

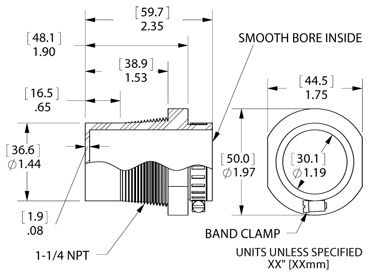

Optional

Mounting Well |

|

|

|

Specifications |

|

Model

PAC-30U: |

Housing: |

Thermoplastic

Polyester |

Enclosure

Protection: |

IP67

(NEMA 4 equivalent) |

Power

Requirements: |

20-265

VAC, 45-65 Hz |

Mounting

Thread Size: |

M30

x 1.5 |

Sensing

Distance: |

4

to 25 mm adjustable |

Indicator: |

LED,

yellow |

Output: |

Normally

Closed or Normally Open, Switch Selectable |

Leakage

Current: |

<2.5

mA |

Load

Current: |

10-500

mA |

Frequency

of Operating Cycle: |

25

Hz |

Operating

Temperature: |

-13° to

176° F (-25° to 80° C) |

Electrical

Connections: |

Cable,

6ft(1.8m), 18-20 AWG |

Max. Pressure: |

1.4 psi |

Max. Pressure:

(with mounting well)

|

125 psi |

Approvals: |

UL/CSA

General Purpose; CE Mark |

Model PDC-30: |

Housing: |

Thermoplastic Polyester |

Enclosure Protection: |

IP67 (NEMA 4 equivalent) |

Power Requirements: |

10-40 VDC |

Mounting Thread Size: |

M30 x 1.5 |

Sensing Distance: |

0 to 25 mm adjustable |

Output Indicator:

Stable Indicator:

|

LED, yellow

LED, green |

Output: |

13-8231, NPN (sinking)

13-8241, PNP (sourcing) |

Consumption: |

<12.0 mA |

Load Current: |

0-200 mA |

Frequency of Operating Cycle: |

100 Hz |

Operating Temperature: |

–22° to 185° F (-30° to 85° C) |

Electrical Connections: |

Cable, 6ft(1.8m), 18-20 AWG |

Max. Pressure: |

1.4 psi |

Max. Pressure:

(with mounting well) |

125 psi |

Approvals: |

CE Mark |

|

|

|

Warranty |

|

Monitor

Technologies warrants each proximity switch it manufactures

to be free from defects in material and workmanship under

normal use and service within two (2) years from the date

of purchase. The purchaser must notify Monitor of any

defects within the warranty period, return the product intact,

and prepay transportation charges. The obligation of Monitor

Technologies LLC under this warranty is limited to repair

or replacement at its factory. This warranty does not apply

to any product which is repaired or altered outside of Monitor

Technologies' factory, or which has been subject to misuse,

negligence, accident, incorrect wiring by others, or improper

installation.

|

|

Updated September 14, 2021 |

|

|

|

|

|

|

|

|

QuantiMassTM

Mass Flow Measurement Systems |

The QuantiMass in-line mass flow sensor measures the flow of quantities in pneumatic conveying & free-falling processes. The sensor is based on the latest Microwave Doppler Effect technology and provides fast, in-line / on-line measuring without the use of weight scales.

The sturdy, non-intrusive design of the sensor minimizes maintenance. In addition, the compact size of the sensor makes for easy installation into existing processes. Suitable for powders, dust, pellets, and granular up to 0.75 inch (2cm).

Versions:

Ultra Series-Includes controller

PRO Series-Includes transmitter

A practical application for the QuantiMass would be to monitor material flow rates to verify blending mixture ratios.

Principle of Operation:

The QuantiMass Mass Flow Measurement Sensor / Meter is designed with the latest microwave technology and is used to continuously quantify the flow of powders & solids being conveyed in metallic pipes. The QuantiMass is based on technology that has been developed and proven over several years. The measurement process of the sensor is centered on the Doppler effect. The mass flow-rate is determined by evaluating the frequency and amplitude changes during the measurement process. Particles at rest, such as deposits, do not influence the measurement. All powders, dust, pellets and granules can be measured reproducibly, up to the size of 0.75 inch (2cm). The QuantiMass sensor is suitable for continuous in-line / on-line measurements in pneumatic conveying or in free-fall pipelines.

Click

here for more information on the QuantiMass

or

contact Monitor Technologies LLC at

Tel.: 800-601-6319 in the USA and

Tel.: 630-365-9403

worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|