Quanti MASSTM MASS FLOW MEASUREMENT Sensor

|

|

|

|

|

|

|

|

|

Support Documents:

| QuantiMass Ultra Product Sheet | |

|

QuantiMass PRO Product Sheet |

|

|

Application Questionnaire (Excel) |

Similar Item(s):

Models SFD-2 and SFI Solids Flow Monitors

Principle of Operation

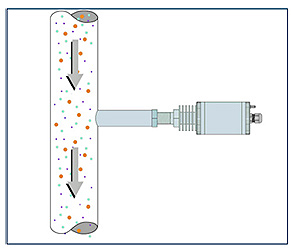

The QuantiMass Mass Flow Measurement Sensor / Meter is designed with the latest microwave technology and is used to continuously quantify the flow of powders & solids being conveyed in metallic pipes. The QuantiMass is based on technology that has been developed and proven over several years. The measurement process of the sensor is centered on the Doppler effect. The mass flow-rate is determined by evaluating the frequency and amplitude changes during the measurement process. Particles at rest, such as deposits, do not influence the measurement. All powders, dust, pellets and granules can be measured reproducibly, up to the size of 0.75 inch (2cm). The QuantiMass sensor is suitable for continuous in-line / on-line measurements in pneumatic conveying or in free-fall pipelines.

Applications

Typical Applications include, but are not limited to:

> Feed and grain industries

> Food industry

> Building materials industry

> Wood dust

> Coal dust

> Ceramics production

> Cement industry

> Chemical industry

> Detergent industry

> Fertilizer industry

> Glass production

> Metal production

> Pharmaceuticals

> Pigment production

> Plastic industry

> Rubber goods

> Recycling industry

> Synthetic materials

> Textiles production

> Tobacco industry

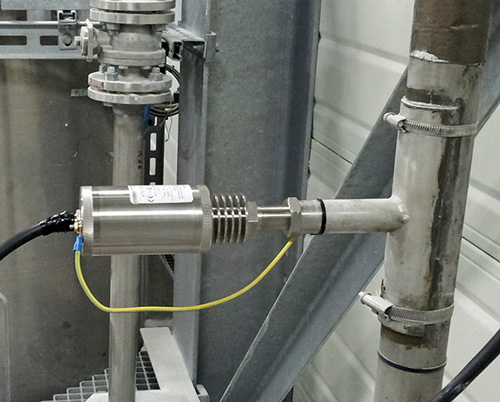

In-Line Mass Flow Measurement Application Examples:

Mass flow sensor in a dry sand application |

Mass flow measurement for coal dust burner injection |

||

Mass flow sensor in a plastic powder application |

Mass flow sensor in a cement application |

||

|

Mass flow measurement for feed pellets |

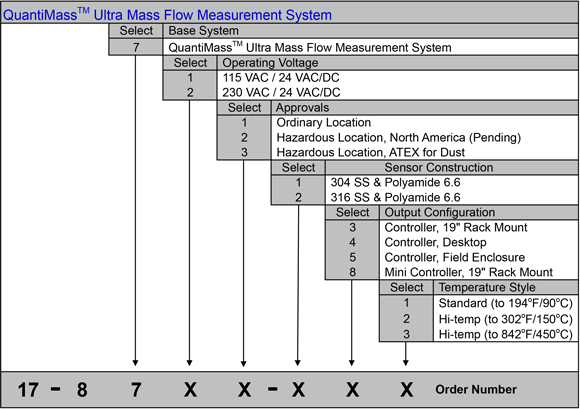

Version Selection

Ultra Series

A complete QuantiMass Ultra system consists of the controller and the sensor. The controller provides graphic user interface with softkeys and a clearly arranged display of the measured, alarm and MIN/MAX values, combined with easy editing and parameterization for simple operation. In addition, up to 24 different product parameters can be stored in the controller to accommodate product or process changes. The Ultra series controller has an Integrator / Totalizer feature that provides a sum of the mass flow for a period of time.

A complete QuantiMass Ultra system includes a sensor and controller.

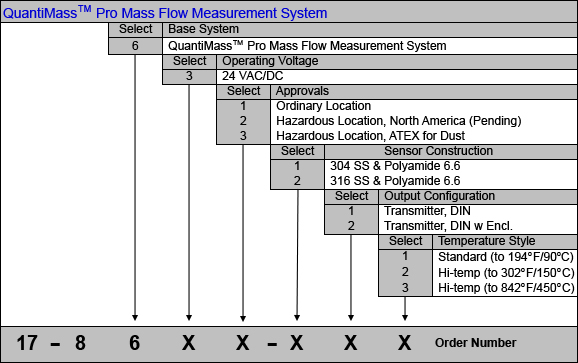

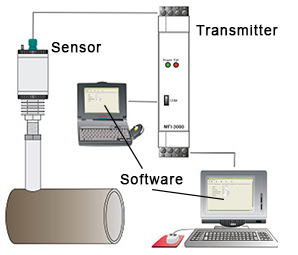

PRO Series

A complete QuantiMass PRO system consists of the DIN-Rail transmitter and the mass flow measurement sensor. The DIN-Rail transmitter allows for easy integration into an existing control system. Calibration software is provided. In addition, up to 24 different product parameters can be recorded to accommodate product or process changes.

(Optional BCD Product Characterist Switching - Up to 15 Product Char.)

A complete QuantiMass Pro system includes a sensor, DIN-rail Transmitter and Configuration Software.

Ordering Information

ACCESSORIES:

Part #, Description

17-3401, Welding Branch, Steel

17-3402, Welding Branch, 304 SS

17-3403, Welding Branch, 316 SS

R0514-18001, Cable, 4-Wire, Shielded, 18 AWG (1)

Note:

(1) Cable is not included. Must be ordered separately.

-------------------------------------------------------------------------------------------