| |

PRODUCTS

|

|

|

|

|

|

|

WirelessEZ

Communication Interface

|

Shown with standard

range antenna

(flexible rubber style)

|

|

|

Provides wireless communication for the SiloPatrol SE SMU, RadarRight or customer-supplied sensors utilizing half-duplex RS-485 communications.

|

|

Overcomes

physical obstacles to wiring

|

|

Eliminates half-duplex RS-485 sensor

communication wiring & reduces installation costs

|

|

Suitable for wire-replacement application(half-duplex RS-485) |

|

Easy set-up...radio channels & communication / serial ports are pre-programmed at the factory based on your rquirements |

|

High

reliability with frequency-hopping spread-spectrum technology

|

|

Long range

900MHz band

|

|

Universal 85 to 265 VAC power supply |

| |

|

|

|

|

|

|

|

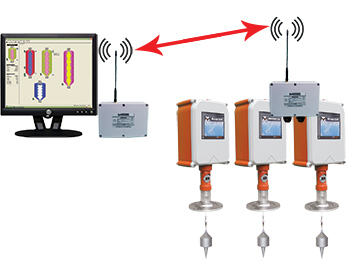

The WirelessEZ Communication Interface (radio modem) is compatible with the the SiloPatrol® SE (SMU) "smart" cable-based sensor, RadarRight non-contact level sensor or Flexar guided wave radar level sensor. It can also be used for wire-replacement applications for equipment not manufactured by Monitor Technologies (consult factory for details). Communication between the sensors and an operator interface like the HMI2 control console or the SiloTrack PC or CLOUD inventory management software is accomplished via half-duplex (2-wire) RS-485 communication format. The WirelessEZ Communication Interface can be used to replace the RS-485 wiring between the sensors, the HMI2 or the PC. The WirelessEZ Communication Interface can be used to lower the cost of some installations and to overcome obstacles that make hardwiring impractical or impossible.

The WirelessEZ Communication Interface uses proven frequency-hopping spread-spectrum technology, operating in the 900MHz band, to communicate between two points. The 900MHz band is a FCC license-free band and offers greater transmission distances, better signal transmission through obstructions and lower signal loss than other available higher frequency bands.

The WirelessEZ Communication Interface has a durable powder-coated die cast aluminum housing and is provided with a mounting bracket that can be used for affixing to a flat surface or pipe / railing. Each transceiver includes RS-485 half-duplex (2-wire) interface.

With reliable and affordable technology, the WirelessEZ

Communication Interface can be used to lower the cost of

installation and to overcome obstacles that make hardwiring

impractical or impossible.

|

|

Principle of Operation |

|

OPTIMIZED

RELIABILITY

The WirelessEZ Communication Interface uses proven frequency-hopping spread spectrum technology,

operating in the 900MHz band, to communicate between your PC running SiloTrack Server

software, the SiloTrack CLOUD Gateway or HMI2 control console and

individual or groups of SiloPatrol® SE (SMU) "smart" sensors or RadarRight non-contact radar sensors.

The 900MHz band is a FCC license-free band and offers greater transmission

distances, better signal transmission through obstructions and lower signal

loss than other possible frequency bands.

Frequency-hopping spread-spectrum

radio technology utilizes a band of frequencies between 900-928MHz and continuously "hops" or

switches frequencies during radio transmission enhancing reliability and minimizing

disruption of the telecommunications. The spread-spectrum enables a signal

to be transmitted across a frequency band that is much wider than the minimum

bandwidth required by the information signal. This reduces interference and allows for increased data communication.

FLEXIBILITY

The WirelessEZ

Communication Interface can be utilized in numerous applications, even with

multiple sensor networks and over 100 sensors. Each sensor network will require

a wireless modem/transceiver at the PC. A wireless modem/transceiver is also required at

the sensor(s) location. SM, RadarRight and Flexar sensors need to reside on separate RS-485 networks.

|

Single

Network/Point-to-Point: One transceiver

is located at the PC and one at a group of sensors

or at a single sensor. If used with a grouping of

sensors located in close proximity, the sensors would

be wired together with the transceiver.

Single

Network/Multiple-Point: One transceiver is located at

the PC and one transceiver at each of multiple groups

of sensors within a single network or one transceiver

at each sensor.

|

Multiple

Networks/Point-to-Point: One transceiver for each network

of sensors at the PC and one transceiver at each network

group of sensors.

|

Multiple

Networks/Multiple-Point: One transceiver is located

at the PC for each network and one transceiver at each

of multiple groups of sensors within each network or

one transceiver at each sensor within each network.

|

|

|

Model Selection |

|

The WirelessEZ

Communication Interface has a powder

coated die cast aluminum housing that

is suitable for indoor or outdoor mounting and is provided

with a mounting bracket that be used for mounting on a flat

surface or pipe/railing.

A choice of antenna is provided

(standard or high gain).

Radio channels & communication / serial ports are pre-programmed at the factory based on your rquirements:

> Select communication protocol: SMU, RadarRight, Flexar or customer - specified

> Select radio channel #: 1-10, Channel #1 is standard

|

|

Specifications |

|

Power

Requirements: |

85 to 265

VAC (±15%); 8VA; 50/60Hz |

Ambient

Operating Temp: |

-40° to

+150° F (-40° to +65° C) |

Data

Input Signal: |

RS-485

half-duplex, isolated |

Alt.

Data Input Signal: |

RS-232, isoltated |

Wiring

Distance: |

3,279

ft. (1,000 m) |

Radio

Output: |

900MHz

(North America); 1W |

Radio

Sensitivity: |

-110dBm |

Conduit

Entry: |

Two

(2) 0.88in (22.4mm) dia. holes |

Indicators: |

Orange

LED: Tx

Yellow

LED: Rx

Green LED: Power |

Housing: |

Powder

coated die cast aluminum,

IP66

|

Mounting: |

Desk,

wall or pipe/rail |

|

|

|

Warranty |

|

Monitor

Technologies LLC warrants each WirelessEZ Interface it manufactures to be free from defects in material

and workmanship under normal use and service for two (2)

years from the date of purchase. The purchaser must notify

Monitor of any defects within the warranty period, return

the product intact, and prepay transportation charges. The

obligation of Monitor Technologies LLC under this warranty

is limited to repair or replacement at its factory. This

warranty does not apply to any product which is repaired

or altered outside of Monitor Technologies' factory, or which

has been subject to misuse, negligence, accident, incorrect

wiring by others, or improper installation. Monitor Technologies

LLC reserves the right to change the design and/or specifications

without prior notice.

|

|

Updated July 2021 |

|

|

|

|

|

|

|

|

QuantiMassTM

Mass Flow Measurement Systems |

The QuantiMass in-line mass flow sensor measures the flow of quantities in pneumatic conveying & free-falling processes. The sensor is based on the latest Microwave Doppler Effect technology and provides fast, in-line / on-line measuring without the use of weight scales.

The sturdy, non-intrusive design of the sensor minimizes maintenance. In addition, the compact size of the sensor makes for easy installation into existing processes. Suitable for powders, dust, pellets, and granular up to 0.75 inch (2cm).

Versions:

Ultra Series-Includes controller

PRO Series-Includes transmitter

A practical application for the QuantiMass would be to monitor material flow rates to verify blending mixture ratios.

Principle of Operation:

The QuantiMass Mass Flow Measurement Sensor / Meter is designed with the latest microwave technology and is used to continuously quantify the flow of powders & solids being conveyed in metallic pipes. The QuantiMass is based on technology that has been developed and proven over several years. The measurement process of the sensor is centered on the Doppler effect. The mass flow-rate is determined by evaluating the frequency and amplitude changes during the measurement process. Particles at rest, such as deposits, do not influence the measurement. All powders, dust, pellets and granules can be measured reproducibly, up to the size of 0.75 inch (2cm). The QuantiMass sensor is suitable for continuous in-line / on-line measurements in pneumatic conveying or in free-fall pipelines.

Click

here for more information on the QuantiMass

or

contact Monitor Technologies LLC at

Tel.: 800-601-6319 in the USA and

Tel.: 630-365-9403

worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|