Dust TREND(TM) ES PARTICULATE EMISSION TREND MONITOR

|

|

|

|

|

|

|

|

|

Support Documents / SOFTWARE:

| DustTrend ES Product Sheet | |

|

DustTrend ES & DustConfig Manuals |

|

| Application Questionnaire | |

| 2D Drawings & 3D Models - Registration Required | |

|

DustConfig Software |

Similar Item(s):

DustAlarm ES Broken Bag Detector

Principle of Operation

AC Triboelectric technology has been used for broken bag detection for many years and is an accepted technology by the US EPA for dust particle emission detection (40 CFR Sec 63.1350).

The Triboelectric effect is based on particles interacting with an electrically isolated sensing probe. When moving particles pass in close proximity to the probe a very small electrical charge is transfered from the particulate to the probe. This electrical signal is then processed by the DustTrend® ES via a series of advanced algorithms. The signal processing filters out other electrical charges, or electrical ‘noise’, which is not representative of the moving particles. These proprietary algorithms effectively differentiate undesirable signals from the desirable signal resulting in reliable particle emissions detection.

The DustTrendTM ES is designed to provide a relative measurement of the concentration of dust within the exhaust air stream of a dust collection system and can also provide alarm outputs when pre-set thresholds are exceeded.

Auto Set-up Feature:

Using the Auto Set-up method will automatically configure these parameters:

{ Running average of measured signal: 100 sec time constant default

{ 4mA: 0x measured value from Auto Set-up default

{ 20mA: 20x measured value from Auto Set-up default

{ Alarm-1 threshold: 5x measured value from Auto Set-up default

{ Alarm-2 threshold: 20x measured value from Auto Set-up default

{ Alarm delay, hold on: 30 sec default

{ Alarm delay, hold off: 30 sec default

Outputs:

The DustTrendTM ES provides 4-20mA Analog, Relay and/or RS-485 (Modbus) Digital outputs.

Applications

Typical target materials for this switch include, but are not limited to:

Feed and grain, food processing (flour, sugar, etc.), wood dust, cement, fly ash, foundries, mining and minerals, steel, ferrous or non-ferrous metals, silica dust, energy, plastics, pharmaceutical, chemical processing and more.

Provides monitoring of dust emission levels and early leak detection where it is critical to safety, maintenance,

equipment operation, cost-savings, reducing material loss, plant efficiency (energy-savings), good “housekeeping”,

employee welfare, environment, local regulations, etc.

Alternative to opacity detection.

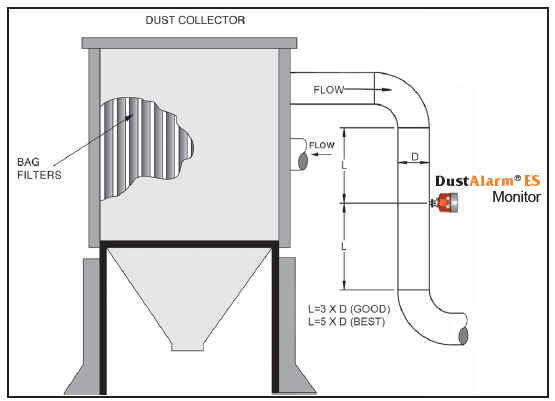

The DustTrendTM ES provides trend monitoring and broken bag detection in the exhaust ducts of baghouses of various sizes, cartridge collectors, cyclones, and any other dust collector containing filters which may break or wear out. [See example below.]

Application Example

Please note from the example, when placing the monitor allow for a distance of 3X to 5X the duct diameter both upstream & downstream from DustTrendTM ES or DustAlarm® ES to allow for ideal dispersion of particulate material.

Options

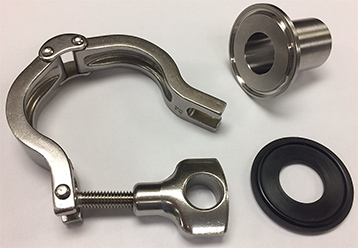

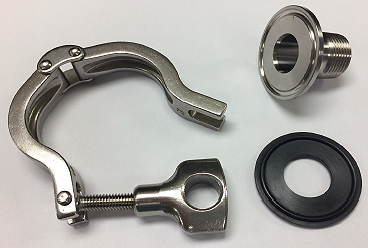

Optional Quick-Connect Mounting Kits:

18-8007 Kit, Mounting, 1” Ferrule Tri-Clamp (Ferrule, Gasket and Clamp)

18-8009 Kit, Mounting, Convert Tri-Clamp to 3/4” NPT (Threaded Ferrule, Gasket and Clamp)

Probes and Probe Extensions:

Available solid coupling probe extensions to provide an additional 2" (51mm) to 24” (610mm) of probe length.

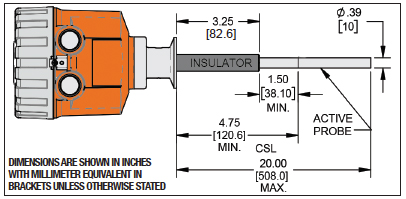

316 Stainless Steel probe standard length up to 20” (508mm).

[Customer specified probe lengths from 4.75” to 20”.]

(CSL) Custom Probe Length Measurements

(It is recommended to use a probe length that is 1/3 to 2/3 the diameter [or span] of the duct.)

Click Here for Reference on How to Determine Overall Insertion Length for Customer Specified Legnths

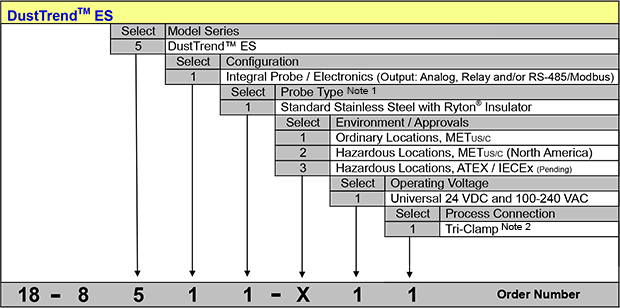

Ordering Information

Need some more information?...Click on the button.

Need some more information?...Click on the button.