duravibeTM Model vibrarodTM vibratory level indicator

|

|

|

|

|

|

|

|

|

Support Documents:

| Model VibraRod Product Sheet | |

| Model VibraRod Manual | |

|

ATEX / IECEx Supplemental (Bulletin #554K) |

|

| Application Questionnaire | |

|

2D Drawings & 3D Models - Registration Required |

Similar Item(s):

DuraVibe(TM) Model PZP Vibratory Level Sensor

Principle of Operation

The DuraVibe™ Model VibraRod™ vibrating point level sensor is a mechanical resonance system that is excited at a resonance by an electrical circuit. Two piezoelectric crystals are mounted internally at the probe’s base. The electronic module generates an electrical signal that has an equivalent frequency to the probe’s resonant frequency; this signal is applied to one crystal, which causes the probe to vibrate. The vibration is monitored by the second crystal which provides an electrical signal back to the electronic module. When material contacts and surrounds the probe, the vibration is dampened and the signal from the second crystal is reduced. This signal reduction is detected by the electronic module, which reacts by providing a signal out of the module through the relay contacts. The sensitivity for the VibraRod is selectable. The single probe design prevents material bridging, which is common with the dual-blade (“tuning fork”) design.

Applications

Typical target materials for this switch include, but are not limited to:

Dry ingredients, whole or ground coffee beans, rice, peanuts, grain, feed pellets/crumbles, tobacco, sawdust, wood shavings, plastic pellets, powdered clay, sand, gravel, cement, lime, chemicals/pharmaceuticals, carbon black and more.

Versatile and durable, yet economical, vibratory solution.

Ideal for reliable detection of materials whose physical characteristics are variable, such as, changes in moisture, temperature, composition or geometric shape.

Excellent for a variety of materials with densities as low as 10 lbs/ft3 (160 kg/m3); with a maximum particle size of about 1 inch (25 mm).

Acceptable for installations where material clings to sidewall as probe is tip-sensitive and unaffected by material build-up near mounting base.

Level detection / back-up protection for dust collection hoppers.

Version Options

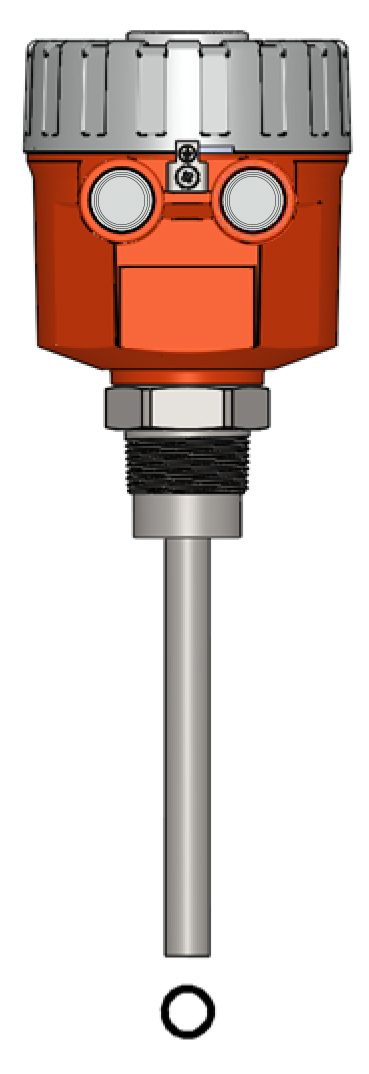

Standard Version:

. Single probe design

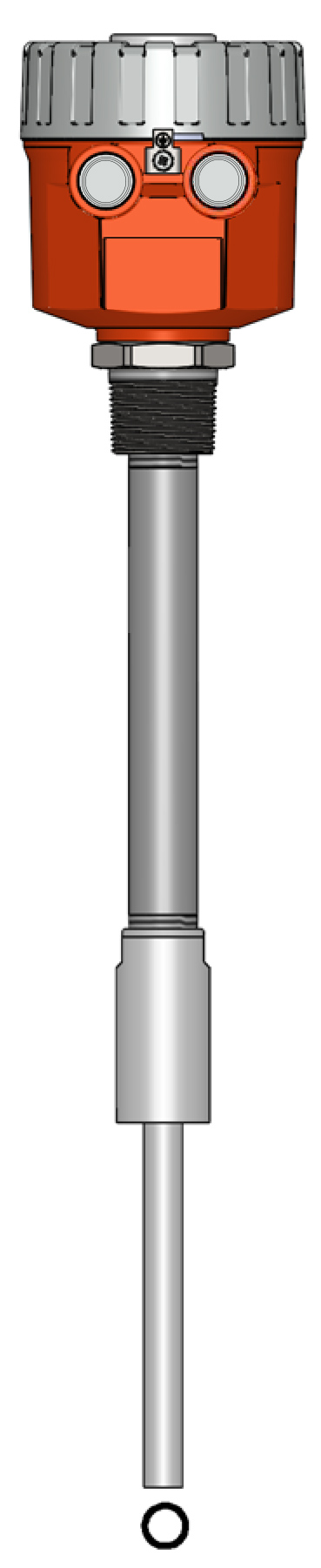

Pipe Extensions:

. For high and low level applications that extend beyond the length of a standard probe.

. Top-mount is intended for high-level applications only and is suitable for lengths up to 6’ (1.8m).

. Side-mount is acceptable for short lengths and where probe is properly supported.

Click Here for Reference on How to Determine Overall Insertion Length for Customer Specified Legnths

Process Connections / Reducer Fittings:

. 1-1/2” NPT x 1-1/4” NPT to attach VibraRod to a 1-1/2” ANSI pipe thread opening (Part #9-0101)

. R 1-1/2” [BSPT] x 1-1/4” NPT to attach VibraRod to a 1-1/2” BSP/ISO pipe thread opening (Part #9-0102)

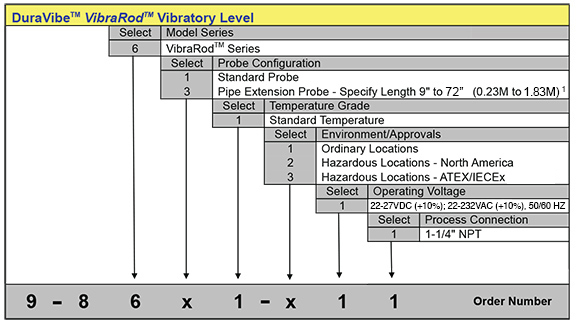

Ordering Information

Need some more information?...Click on the button.

Need some more information?...Click on the button. Discontinued VibraRod Series #9-84xx

Discontinued VibraRod Series #9-84xx