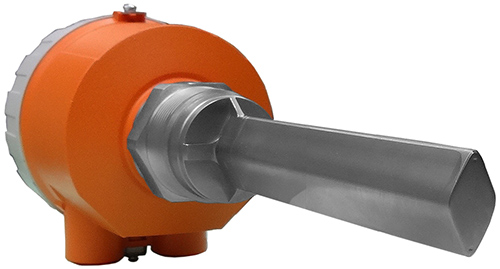

DuravibeTM model PZP vibratory level sensor

|

|

|

|

|

|

|

|

|

Support Documents:

| Model PZP Product Sheet | |

| Model PZP Manual | |

| ATEX / IECEx Supplemental (Bulletin #564K) | |

| Application Questionnaire | |

| 2D Drawings & 3D Models - Registration Required |

Similar Item(s):

DuraVibe(TM) Model VibraRod(TM) Vibratory Level Sensor

Principle of Operation

The DuraVibe™ Model PZP point level sensor is a mechanical resonance system that is excited at a resonance by an electrical circuit. Two piezoelectric crystals are mounted internally at the probe’s base. The electronic module generates an electrical signal that has an equivalent frequency to the probe’s resonant frequency; this signal is applied to one crystal, which causes the probe to vibrate. The vibration is monitored by the second crystal which provides an electrical signal back to the electronic module. When material contacts and surrounds the probe, the vibration is dampened and the signal from the second crystal is reduced. This signal reduction is detected by the electronic module, which reacts by providing a signal out of the module through the relay contacts. The sensitivity for the PZP is selectable. The single probe design prevents material bridging, which is common with the dual-blade (“tuning fork”) design.

Applications

Typical target materials include, but are not limited to:

Sugar, flour, spices, salt, powdered milk, tea(leaf), whole or ground coffee beans, rice, peanuts, feed & grain, tobacco, ice chips, sawdust, wood shavings, chalk, chemicals, polystyrene beads, Styrofoam®, plastic pellets, cellulose, glass, powdered clay, carbon black, foundry sand, gravel, cement, fly ash and more

Ideal choice for reliable detection of materials whose physical characteristics are variable, such as, changes in moisture, temperature, composition or geometric shape.

Suitable for storage vessels where material is regularly changed. For example, one day corn is stored and then another day beans are stored.

Excellent for extremely lightweight materials with densities as low as 1.5 lb/ft3 (20 kg/m3); with a maximum particle size about 1.6 inches (40 mm).

Acceptable for installations where material clings to sidewall as probe is tip-sensitive and unaffected by material build-up near mounting base.

Level detection / back-up protection for dust collection hoppers.

Version Options

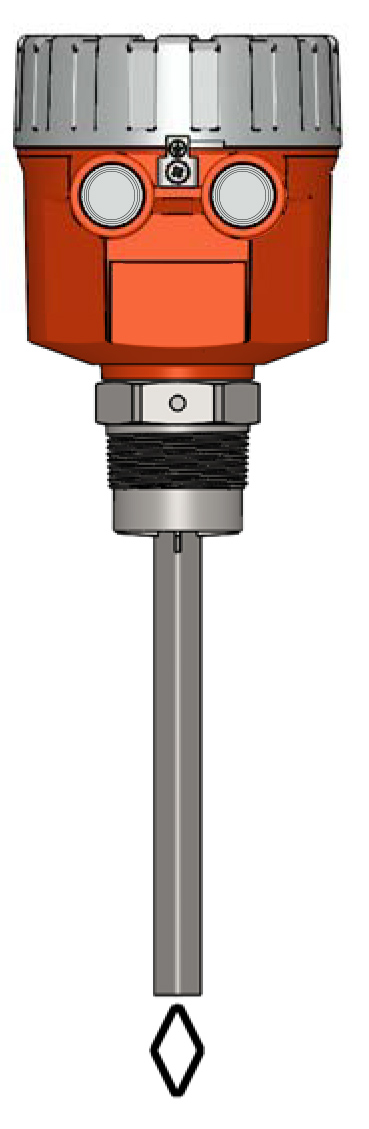

Standard Version:

. Single, diamond-shaped probe design

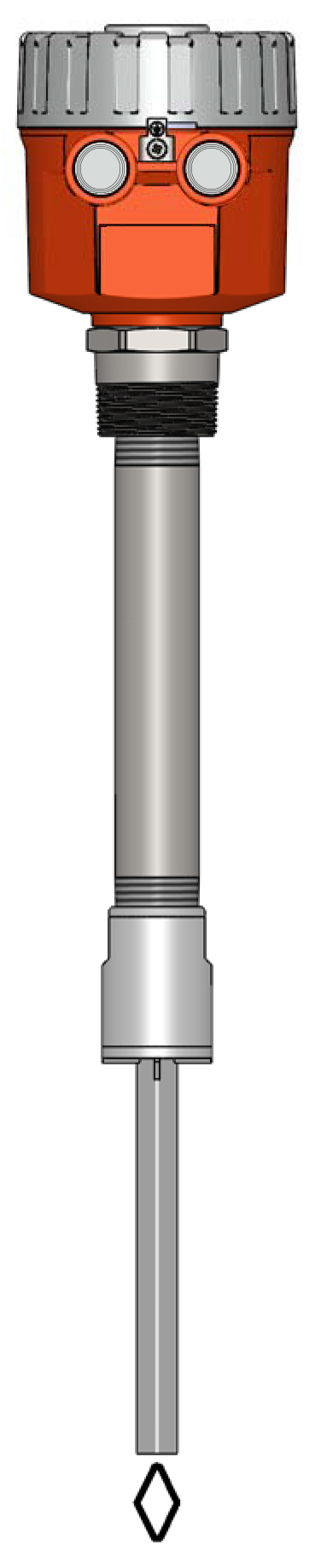

Pipe Extensions:

. For high and low level applications that extend beyond the length of a standard probe.

. Top-mount is intended primarily for high-level applications and is suitable for lengths up to 12’ (3.6m).

. Side-mount is acceptable for short lengths and where probe is properly supported.

Click Here for Reference on How to Determine Overall Insertion Length for Customer Specified Legnths

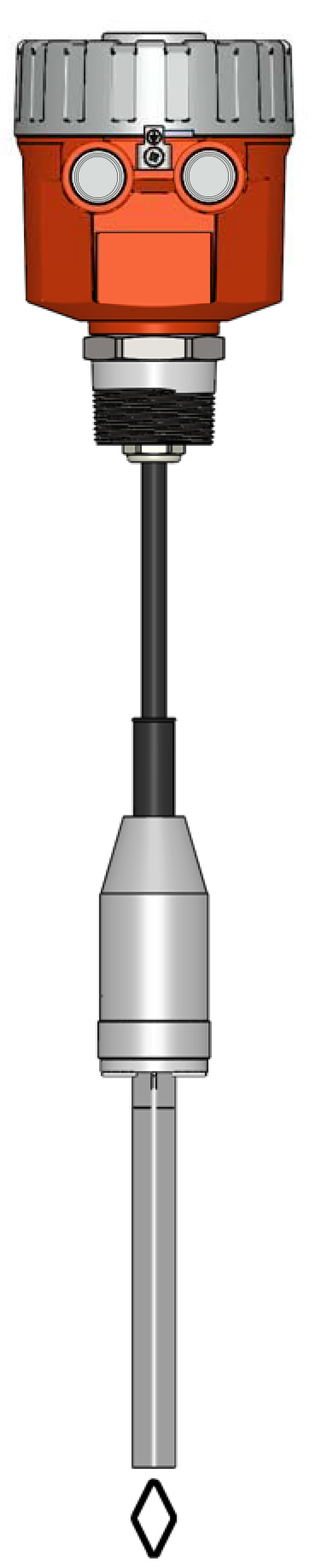

Cable Extensions:

. For top-mount, high-level applications where head clearance prohibits mounting of pipe extension or where free-hanging weight is preferred.

. Suitable for lengths up to 20’ (6.1m).

Click Here for Reference on How to Determine Overall Insertion Length for Customer Specified Legnths

High Temperature / Remote Electronics:

. For applications where it is necessary to keep the electronics away from the vessel due to excessive temperatures or vibration.

. Interconnection of sensing probe and electronics is done by a conduit.

. Standard separation distance is 6’ (1.8m).

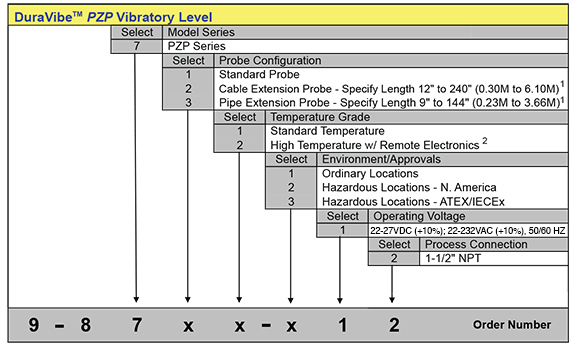

Ordering Information

Need some more information?...Click on the button.

Need some more information?...Click on the button. Discontinued PZP Series #9-83xx

Discontinued PZP Series #9-83xx