Models KA / KAX Rotary

Paddle Level Switches

|

|

|

|

|

|

|

|

|

Similar Item(s):

SafePoint® Fail-Safe Rotary Paddle Level Sensor

Principle of Operation

The operation of Monitor's rotary paddle bin level switch is quite simple. The unit is installed through the wall of the vessel, so that the paddle protrudes inside the vessel. A small electric motor drives a paddle which rotates freely in the absence of material.

When the paddle is impeded by material, the motor rotates within the housing which triggers two switches. The first switch is a “dry” electrical contact closure that is available to control a process function or alarm circuit. The second switch cuts the power to the motor, preventing a locked rotor condition, thus extending motor life. This also activates the signaling device which is wired through that same motor switch. When the material level drops, the loaded stretched tension spring returns the motor to its original running position and the unit is reactivated.

Applications

Monitor’s rugged, reliable design make the paddle bin level indicator (sensor de nivel) compatible with many granular, pelletized and powder bulk applications. Monitor paddle switches can be used for high level indication of materials over 10 lb/ft³ (160 kg/m³ ) and for low and intermediate level indication for materials over 5 lb/ft³ (80 kg/m³). Monitor paddle units can be installed almost anywhere dry bulk materials are stored, including bins, hoppers, silos and tanks. Monitor’s KA unit is the most popular of our paddle bin monitors. This model is ideal for use in standard applications with a wide variety of materials. The KAX incorporates all the features of the KA model, but is specially designed to meet explosion-proof standards.

Typical Applications include, but are not limited to: |

||

Feed |

Silica Sand |

Rocks |

Pellets |

Wood |

Calcium Dust |

Rubber |

Metals |

Regrind |

Coal |

Peanuts |

Malt |

Clays |

Resin |

Limestone |

Grain |

Foundry Sand |

Pre-Mix Ingredients |

Rawhide |

Sawdust |

Coffee |

Features

|

Complete motor shutoff prevents motor burnout and extends the life of the unit |

|

Twist on/off cover means no bolts to hold or lose - Hassle- free housing design |

|

UL, CSA and ATEX/IECex hazardous location approvals (KAX) |

|

1-1/4” NPT or 1-1/2” BSPT process connection |

|

Two conduit connections provide easy wiring access (M20 cable glands provided with Model KA units with BSPT process connection) |

|

Built-in slip clutch protects motor and drive gears from excessive rotational forces |

|

Three bearing design with sealed bearings fully minimizes drive shaft loads and drag providing extended life. |

|

Interchangeable paddle assemblies increase the paddle unit’s versatility |

|

Built-in signal delay prevents false signaling |

|

Field adjustable sensitivity |

|

High operating temperature up to 300°F (149°C) (Hi-temp version up to 750°F (399°C)) |

Available Models

Monitor’s KA unit is the most popular of our paddle bin monitors. This model is ideal for use in standard applications with a wide variety of materials. The KAX incorporates all the features of the KA model, but is specially designed to meet hazardous location standards.

This installed KA unit is being used

as a high-level alarm

in a grain storage

application.

Available Configurations

MOTOR

VOLTAGES

Monitor offers several motor voltages to serve most power requirements.

Available AC motors include 115 VAC, 230 VAC, 24 VAC and 48 VAC.

Superior 12/24 VDC design available uses low voltage AC motor

for longer life in all applications. View DC Powered Technical Sheet (PDF).

|

|

Model KA, 115 VAC, p/n 1-8301-1 |

Model KA, 12/24 VDC, p/n 1-8331-1 |

OUTPUT

CIRCUITS

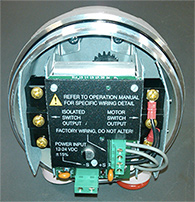

Monitor paddle units are available with 1, 2 or 3 output contacts.

The cost effective 1-circuit model utilizes the motor switch

(SPDT) as the output contact, as long as the alarm device operates

on the same voltage as the motor. The most popular 2-circuit

design contains the motor SPDT switch and a second SPDT isolated

switch for control outputs (See wiring

diagram for illustration). The 3-circuit configuration

provides the user with the SPDT motor switch and an isolated

DPDT switch for control outputs.

PROCESS

CONNECTIONS

Monitor offers a choice of either a 1-1/4” NPT or 1-1/2” BSPT

process connection. Model KA units with the 1-1/2” BSPT

connection also include M20 cable glands.

APPROVALS/LABELING

Monitor paddle units are available approved to UL, CSA and

ATEX/IECex requirements. Various models are approved for

either general purpose, dust/ignition-proof and/or explosion-proof

applications. In addition, all models carry the CE mark.

See “Specifications” section

for more details.

HIGH

TEMPERATURE UNITS

Monitor’s high temperature models incorporate all the

standard features of the KA or KAX models, but can be used

in applications where temperatures reach as high as 750°F

(399°C). The hi-temp models incorporate a specially designed

mounting plate, pipe extension with air purge connection, shaft

extension, couplings and bushings. The high-temp assembly is

available in either a carbon steel or stainless steel version.

See “Ordering Information” for

applicable part numbers.

Accessories

PADDLE

ASSEMBLIES

Monitor offers a variety of interchangeable paddle assemblies

to meet the needs of a wide variety of applications. Different

material densities, particle sizes and flow characteristics require

specific paddles to provide optimum performance. View Paddle Assembly

Selection Guide (PDF).

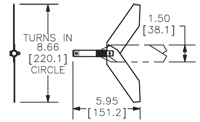

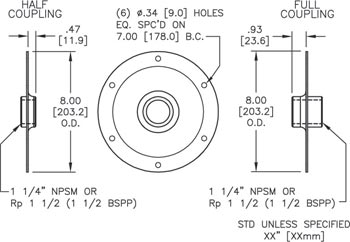

Dimensions are shown in inches with millimeter equivalent in brackets.

1.)

Standard Stainless Steel Three Vane Paddle: The most

popular of all paddles. For use with average weight

materials. |

|

2.) Large Stainless Steel Three Vane Paddle: Provides accurate level control for lightweight materials. P/N 1-4141 |

|

3.) Insertable* Stainless Steel,

Two Vane Collapsible Paddle: Provides low and high level

control for light to average weight materials. |

|

4.)

Insertable* Stainless Steel, Scimitar Single Vane Paddle:

Provides low and high level control for light to average

weight materials. |

|

5.) Insertable*, Stainless Steel Single Vane Paddle: Provides low level control for average weight materials and low to high level control for heavy materials under 1-1/2 inch (40 mm) in diameter. P/N 1-4145 |

|

6.)

Stainless Steel, Two Vane Paddle: Provides low and

high level control for heavy materials under 1-1/2 inch

(40 mm) in diameter. P/N 1-4135 |

|

7.)

Stainless Steel Four Vane Paddle: For use with average

to heavy weight materials in low and high level control

installations. |

|

8.) Stainless Steel Triangular Arc Single Vane Paddle: Provides low and high level control for light to average weight materials. P/N 1-4144 |

|

9.) Ex-Flex Three-Ply 20 inch (508 mm) Belt Paddle: Provides low and high level control for heavy materials over 2 inch (50 mm) in diameter. Top mount only. P/N 1-4137 |

|

*Insertable paddles eliminate the need for a mounting plate. P/N 1-4161 and 1-4193 are insertable through either a half or full 1-1/4” or 1-1/2” coupling, that is welded to the bin wall. P/N 1-4145 is insertable through a half 1-1/4” or 1-1/2” coupling. |

|

|

|

MOUNTING

PLATES

Mounting plates allow the paddle units to be mounted from the

outside of a vessel to curved or flat surfaces. All mounting

plates featured below mount via six bolts.

1.) Half Coupling Mounting Plate: For use in side mount installations. Available in powder coated carbon steel for general purpose applications and stainless steel for use in corrosive environments. Stainless Steel Plate: P/N 1-0112. Carbon Steel Plate: P/N 1-0101 for 1-1/4” NPT connection and P/N 1-0100 for 1-1/2” BSPT connection.

2.) Full Coupling Mounting Plate: For use in top mount installations where a shaft extension and shaft guards are required. Available in powder coated carbon steel for general purpose applications and stainless steel for use in corrosive environments. Stainless Steel Plate: P/N 1-0113. Carbon Steel Plate: P/N 1-0102 for 1-1/4" NPT connection and P/N 1-0115 for 1-1/2" BSPT connection.

3.) K-Flange Aluminum Mounting Plate: For flat surfaces or thin walled vessels where extra strength is required. Ideal for semi-corrosive environments, including out doors. P/N 1-3316.

Dimensions are shown in inches with millimeter

equivalent in brackets.

SHAFT

EXTENSIONS

Many top mount installations require that the paddle extends

into the vessel to a predetermined level. Solid shaft extensions

are available in a variety of lengths up to 144 inches (3.6

m) to meet these demands. A flexible cable extension is also

available. This 6.5 foot (2.0 m) flexible extension can be

easily shortened in the field by the user. The use of the

flexible cable extension for lengths greater than 3 feet

(0.9m) requires the use of a guard to ensure proper activation

of the rotary paddle bin monitor.

SHAFT

GUARDS

Shaft guards are recommended for use with solid shaft extensions

to limit the movement caused by side loading that would otherwise

damage the working components of the paddle unit. Shaft guards

should be the same length as the extension and should always

be used when the extension meets or exceeds 18 inches (460

mm) in length.

Specifications

Power Requirements: |

115

VAC (+/- 10%), 50/60 Hz; |

|||||||

Power Consumption: |

4W max. |

|||||||

Operating Temperature: |

-40°F (-40°C) to +200°F (+93°C) ext. amb.; to +300°F (+149°C) internal bin temperature. High Temp Unit to +750°F (+399°C) internal bin temperature |

|||||||

Conduit Connection: |

Two (2) 3/4" NPT; M20 cable glands (Model KA units with 1-1/2” BSPT process connection only;Not on KAX units) |

|||||||

Outputs Contacts: |

||||||||

2-Circuit Configuration |

Two SPDT 15A @ 250 VAC ea. max |

|||||||

3-Circuit Configuration |

One

SPDT 15A @ 250 VAC max |

|||||||

Maximum Pressure: |

30 PSI (2 bar) maximum |

|||||||

Sensitivity: |

5 lb/ft³ (80 kg/m³) minimum material density (when using large 3-vane paddle) |

|||||||

Housing: |

Die cast aluminum, NEMA 4 / ENCLOSURE TYPE 4, IP66 |

|||||||

Housing Finish: |

Powder coating |

|||||||

Mounting Connection: |

1-1/4" NPT or R 1-1/2 (BSPT 1-1/2) |

|||||||

Shipping Weight: |

Approx. 7 lbs (3.2 kg) |

|||||||

Materials of construction/accessories:

|

||||||||

Listings/Approvals:

|

||||||||

Need some more information?...Click on the button.

Need some more information?...Click on the button.