Silo Patrol® Plumb Bob Style Level Sensor

Similar Item(s):

|

|

| RadarRight(TM) Non-Contact Continuous Level Sensor |

The Silo Patrol® SE Inventory Management System is an industry-leading cable-based smart level sensor system that is designed to handle some of the harshest and most dynamic conditions. The Silo Patrol SE system incorporates state-of-the-art sensors, a wide choice of operator interfaces, auxiliary outputs and displays, as well as unique remote/vendor managed inventory solutions. The Silo Patrol SE delivers a truly robust level sensor design, providing reliable and high value solutions for a wide variety of applications and industries worldwide. The Silo Patrol SE incorporates significant advances in this field-proven approach to reliably monitoring the level of material in bins, silos and tanks up to 150ft (45.7m) in height. The Silo Patrol SE level sensor technology is suitable for use with a multiplicity of powders, granules, slurries and liquids, even in the most harsh and dynamic conditions. The heart of the Silo Patrol SE level measurement system is the sensor itself. The Model SMU (Silo Monitoring Unit), incorporates technological advancements, requires no field adjustments and its robust design provides virtually maintenance-free operation. The SMU is suited for most any application and can be equipped with a variety of mounting flanges and plumb bobs. The Silo Patrol SE system also offers sensor interface choices:

Principle of Operation

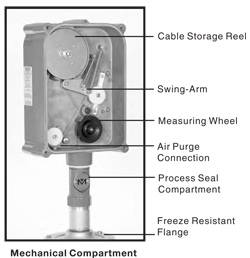

Once a measurement cycle is initiated, the SiloPatrol® SE sensor (SMU) “smart” motor system controls the descent of a plumb bob, attached to a heavy-duty stainless steel cable, into the vessel. The SMU measures the amount of cable dispensed via its unique optical sensing system. The SMU’s optic system is completely sealed from the internal environment of the electronics compartment, which is isolated and sealed from material ingress in the mechanical compartment, to ensure long-term reliable operation. The descent of the bob is maintained at an optimal speed by the “smart” motor control system, contributing to the elimination of cable slack and maximizing the motor life. In conjunction with the unique dual optical sensing system, the “smart” motor control system guarantees that the bob will stop when it contacts the material surface and eliminates the need for a mechanical brake. When the bob reaches the material surface, the SMU reverses the direction of the motor and transmits the distance value. During the ascent of the bob, the SMU measures the amount of cable gathered and controls the speed of ascent. This ensures proper cable wrapping in the patented storage reel and tangle-free operation. In addition, the motor control system has a “Descend-Assist” feature that can be used to prevent the plumb bob from “clinging” to the socket that might occur in extreme applications.

The SMU also includes an innovative Hall-effect sensor array that monitors the movement and position of the swing-arm that controls the absorption of slack in the cable system during descent and ascent. The SMU is smarter than ever and uses this technology to control the cable and plumb bob travel to ensure reliability of the measurement cycle, even with harsh changing conditions in the most severe applications. The standalone versions of the SMU generate a 4-20mA output in response to a measurement query, or automatically with the analog output version. The standard “smart” RS-485 SMU communicates with the operator interface chosen for the system (HMI2 or SiloTrack™ PC software). These operator interfaces can perform calculations and conversions to display the data in the format desired. The RS-485 version of the SMU has Modbus (RTU or Ascii) connectivity to communicate with other operator interfaces or control systems being used at facilities that utilize Modbus. The SiloPatrol SE system, if so equipped, will also generate auxiliary analog and/or relay outputs. RS-485 communications can be accomplished via hardwiring or with wireless transceivers.

Applications

The SiloPatrol® SE Inventory Management System can be used in a wide variety of applications. These include, but are not limited to, simple inventory monitoring with a standalone HMI2 display to Remote and Vendor managed inventory solutions using SiloTrack™ server and client software to manage inventories at multiple facilities while providing access to a virtually unlimited number of users. Materials being monitored include a broad list of powders and bulk solids, as well as, a wide range of liquids and slurries. These include coarse/fine granular solids, powders, liquids, foodstuffs and many other substances.

Typical Applications include, but are not limited to: |

||

Feeds |

Cement |

Bulk Chemicals |

Grains |

Rocks / Aggregates |

Oils |

Plastic Pellets |

Coal |

Some Liquids |

Plastic Regrind |

Sand |

Water / Solid Interface |

Powders |

Limestone |

Coffee |

-------------------------------------------------

REMOTE INVENTORY MONITORING

If material levels need to be monitored at one or many locations (i.e. your facility, a location down the street, or a plant on the other side of the world) the SiloPatrol® SE system can provide accurate and reliable measurements. Using the SiloTrack™ CLOUD web-based app or SiloTrack™ Version 3.5 PC software, inventory monitoring from remote locations has never been easier.

|

|

| SiloTrack™ CLOUD Web-Based Application |

SiloTrack™ PC Software |

-------------------------------------------------

WIRELESS SENSOR COMMUNICATION INTERFACE

While using the SiloPatrol® SE “smart” sensor is the most economical approach available for inventory monitoring, using the available WirelessEZ interface in your application may help you reduce the installed cost of your SiloTrack™ / SiloPatrol SE system even further. The WirelessEZ transceivers use frequency-hopping spread-spectrum wireless technology and operate in the FCC license-free 900MHz band. This provides the longest range and most reliable wireless communications available. Working in conjunction with SiloTrack™ PC-Based inventory management software, the WirelessEZ transceivers provide the most functional and economical inventory management system available today.

Click here for more details on the WirelessEZ and contact our technical support personnel today to see if your application can benefit from a wireless communications solution.

-------------------------------------------------

AUXILIARY OUTPUT ENCLOSURES (AOE)

A unique feature of the SiloPatrol® SE Inventory Management System is the ability to incorporate both relay and analog outputs with a standard "smart" output sensor system. These auxiliary relay and/or analog outputs are provided in Auxiliary Output Enclosures (AOE) and are programmed and controlled by either the HMI2 or SiloTrack™ PC-based Inventory Management Software. One analog output and up to four relays (two for HMI2; four for SiloTrack) can be assigned to each of the “smart” output sensors. These can be used to tie the Inventory Management System into remote control systems, sound alarms and for local control functions. Up to 16 analog outputs or 32 relays can be provided within a single enclosure. Up to four AOE’s can be connected on a single network. The AOE can be located close to the point of hardwiring termination minimizing wiring and installation costs.

2-Card AOE

SMU Electronic Features

|

Industry-exclusive use of magnetic Hall effect sensor technology monitors swing-arm movement and improves overall application reliability and performance, even with the most difficult dynamic conditions |

|

Microcontroller technology provides “smart” motor control, high resolution/accuracy and consistent performance under the most challenging and dynamic conditions |

|

Lock-out input on all models to restrict sensor from initiating a measurement cycle (used to disable measurement during filling operations) |

|

Industry-exclusive electronics certified to international CE 1010 standard ensures compliance in shock hazard protection, electromagnetic noise interference and generation |

|

Complete electrical isolation between inputs/outputs and earth ground eliminates ground loops and ensures proper long-term operation and data communication |

|

Superior resolution of 0.01ft (0.12”; 3mm) |

|

Unique optical measuring system uses an amplification circuit to maximize signal-to-noise performance |

|

Relay output standard on analog output version provides contact closure based on user set level, sensor failure or measurement cycle operating |

|

SMU Mechanical Features

|

Split-compartment enclosure completely isolates electronics from mechanical section of sensor |

|

Industry-exclusive compartment seals optical sensors from internal SMU environment completely eliminating problems created by contamination, even from conduits |

|

Industry-first direct-drive motor and heavy-duty cable system deliver unsurpassed pull strength |

|

Process seal (wiper seal mechanism) easily replaced without removing or cutting cable |

|

Unlike most competitive devices, the SMU wiper seals provide full-circumference wiping of the cable |

|

Freeze-resistant flange can eliminate problems in applications where changing environmental conditions and condensation are present |

|

Patented storage reel incorporates a "step" to ensure non-tangling cable wrap |

|

Cable pathway and storage reel are completely captive, eliminating cable-jump |

|

Wide variety of plumb bobs available including cast aluminum or stainless steel, standard plumb bob, stainless steel inverted cone, Teflon coated, water/solid interface and digestible |

|

Air purge connection enables operation in dynamic, dust-laden applications |

|

SMU Sensor Model Selections

OUTPUT TYPES

Standard "Smart" RS-485:

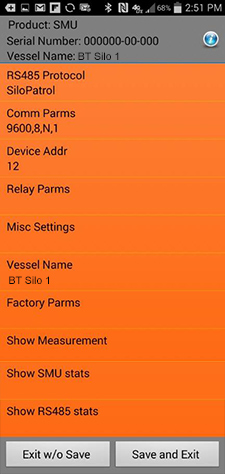

The SMU communicates with the HMI2 or SiloTrack™ PC-based Inventory Management Software via a RS-485 proprietary protocol. Also includes Modbus (RTU or Ascii) connectivity to communicate with other operator interfaces or control systems being used at facilities that utilize Modbus. See Installation Bulletin #344N for SMU Modbus Register Map. Has relay output for high or low distance threshold setting, error indication or cycle operate. In addition, this type of system can also be equipped with auxiliary relay. Includes wireless Bluetooth® set-up that allows operator to utilize a free configuration app on an Android-based device with Bluetooth® capability to easily access and configure the SMU set-up instead of having to open the unit to configure it. Click here to download ConfigureSensor app. (For use with Android-based smartphones & tablets.)

View of Main Menu for

ConfigureSensor App (RS-485)

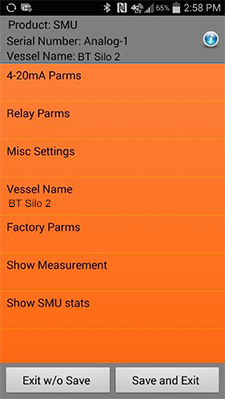

Analog 4-20mA:

This SMU sensor is a standalone transmitter version providing a direct analog signal for each measurement update. Measurements are initiated automatically as setup within the sensor or in response to a remotely activated contact closure. This sensor version is provided with a relay output that can be set to activate when a user established level is reached, upon detection of a sensor error or when a measurement cycle is in process. Includes wireless Bluetooth® set-up. Click here to download ConfigureSensor app. (For use with Android-based smartphones & tablets.)

View of Main Menu for

ConfigureSensor App (Analog 4-20mA)

APPROVALS

The SiloPatrol® SE Model SMU sensor is available certified for either Ordinary or Hazardous locations. The SMU also carries the CE Mark. Consult the Specifications section for further information.

FREEZE-RESISTANT MOUNTING FLANGES SMU sensors can be provided with either the standard flat mounting flange or one of the angled flanges (5° and 10° available) for adapting to sloped roofs. Each of these standard flanges has a unique design that resists freezing of the plumb bob to the underside of the flange. This is especially important in very cold climate conditions where moisture from condensation within the silo can form and create ice on the underside of the silo roof, usually due to cycling above and below freezing temperature in an outdoor installation. In these applications the freeze-resistant flange may eliminate the need for standpipe or flange heating. Contact the factory for modified ANSI/DIN flanges (not “freeze resistant”).

Use of Volume / Weight Calculations

The SiloPatrol® SE Model SMU sensor makes a direct measurement of the distance between the sensor and the material surface. This equipment does not measure the volume or weight of the material within the vessel. The HMI2 and SiloTrack™ PC-based software, when used with a SiloPatrol SE “smart” output sensor, may be able to perform calculations to display the volume and weight of the material. These calculations are based upon the distance measurement and the vessel dimensions and material bulk density entered by the user during setup. Note: The calculated volume and weight values should be considered "estimates". Monitor Technologies LLC accepts no responsibility for the accuracy of the calculated and displayed volume and weight values. The accuracy (not stated or warranted) of the volume/weight calculations are effected by the fluctuation and accuracy of various factors. These factors include, but may not be limited to, actual vessel dimensions, sensor mounting location, angle of repose (negative and positive), material bulk density, material flow properties (ratholes, bridging, etc.), material inlet/discharge locations and material packing. Please consult the factory to discuss applications where volume/weight is of critical importance.

Accessories

PLUMB BOB

ASSEMBLIES

Monitor offers a variety of plumb bob assemblies

to meet the needs of a wide variety of applications.

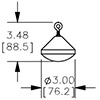

Dimensions are shown in inches with millimeter equivalent in brackets.

1.)

Standard Cast Aluminum - Most SMU sensors are shipped with this #6-3103 plumb bob assembled to the unit. For use with bulk solids with a bulk density greater than 20lbs/ft3 (320kg/m3). A Teflon® coated version is also available for sticky materials. |

|

2.)

316 Stainless Steel - For use with corrosive solids and foodstuffs with bulk densities greater than 20lbs/ft3 (320kg/m3). This plumb bob is typically shipped as a separate item, but can be assembled to the SMU at the factory upon request. |

|

3.) 316 SS Inverted Cone - For use with light bulk solids and foodstuffs with bulk densities approximately 5 lbs/ft3 (80kg/m3) and higher. Teflon®-coated also available for corrosive or sticky materials. This is shipped as a separate line item and must be attached to the cable in the field. |

|

4.) 6 in (152 mm) Diameter 316 SS Ball Float - For use with liquids with a minimum specific gravity of 0.85. A Teflon®-coated version is also available for corrosive or sticky materials. This plumb bob is shipped as a separate line item and must be attached to the cable in the field. |

|

5.) Solid / Water Interface-Style, Stainless Steel Plumb Bob: For use with settled solids in a blanket of water. The interface-style plumb bob will penetrate through the water, make contact with the surface of the solid material and then retract to provide a level measurement. Examples of material applications that have been successful include sand, salt, potatoes, corn, rice and similar items that are covered by a layer of water. Interface with other liquids besides water may also be possible. Please contact Monitor regarding specific applications. This plumb bob is shipped as a separate line item and must be attached to the cable in the field. P/N #6-4112 |

|

6.)

Digestible Plumb Bob: For applications where an unattached metal plumb bob could result in damage to bin discharge equipment. The digestible plumb bob container can be filled with material to achieve a total plumb bob weight of 2 lbs. The container is made of polyethylene. The lid is made of polyacetal (Delrin). The digestible plumb bob interconnection incorporates only one small assembly of metal components. This plumb bob is shipped as a separate line item and must be attached to the cable in the field. P/N #6-2190 |

|

HMI2 Operator Interface Control Console

The HMI2 operator interface control console provides convenient, local interface for Monitor’s “Smart” RS-485 SiloPatrol® SMU SE cable-based inventory monitoring sensors and/or Flexar® guided wave radar sensors. HMI2 allows for monitoring up to 32 SMU and/or Flexar sensors. The multi-functional HMI2 controls sensor operations, displays measured and calculated data and performs/displays system and sensor diagnostic messages. The HMI2 is easily programmed to display calculated level, volume, weight or percent in addition to the basic distance measurement. Manual readings are taken by depressing the MEAS button, followed by the channel number, followed by ENTER. The HMI2 can also be programmed to operate the SMU “Smart” RS-485 sensors automatically. Menu options allow the user to select days of SMU operation (such as Mon.-Fri.), time window (such as 7 a.m.-3 p.m.) and measurement interval (minimum 30 minutes).

Click Here for more details on the HMI2

SiloTrack(TM) CLOUD Web-Based Inventory Management Software

SiloTrackTM CLOUD is a web-based application that places inventory management at your fingertips! Securely access material inventory data from continuous level sensors using any device with Internet connection. Set level alarms and receive e-mail and text notifications. Create & export configurable reports for accounting purposes and to improve inventory efficiencies. Ideal for Remote Managed Inventory (RMI) and Vendor Managed Inventory (VMI) solutions.

Click Here for more details on SiloTracK CLOUD

SiloTrack(TM) PC-Based Inventory Management Software

SiloTrack™ Version 3.5 Inventory Management Software provides users with an unsurpassed, flexible graphical interface for SiloPatrol® SE “smart” output sensors. Together, SiloTrack Server and Client software can provide inventory monitoring and management to a virtually unlimited number of users, both internal and external to your facility. This allows easy implementation of remote monitoring and vendor managed inventory programs.

SiloTrack capabilities include:

-

Monitor up to 128 sensors/with up to 5 sensors per vessel

-

Easy to set up and use

-

Network capable

-

Remote monitoring via LAN, Internet/WAN or dial-up

-

Available in English/Spanish language

-

Automatic and manual measurement initiation

-

Curve-fit weight table

-

Enhanced 3-D type silo graphics

-

Export silo history and alarm data

-

Automatic Reports and Scheduling

-

Set up four alarms per silo

-

Alarm notification via e-mail, fax, etc.

Click Here for more details on SiloTrack

Specifications

SILO MONITORING UNIT (SMU) |

|

Power Requirements: |

115 VAC or 230 VAC(+15%), 50/60 Hz |

Power Consumption: |

6 VA continuous, 50 VA intermittent |

Altitude: |

6562ft (2000m) maximum |

Installation Category: |

II |

Pollution Degree: |

4, Suitable for indoor/outdoor use |

Process Temperature: |

-40° F to 300° F (-40° C to 149° C) |

Ambient Operating Temperature: |

-40° to +150°F (-40° to 65°C) |

Maximum Internal |

Up to 300°F (149°C) with

use of bare stainless steel cable |

| Maximum Vessel Pressure: | 15 PSI |

Measurement Range: |

150 feet maximum (45.7 m) |

Measurement Rate: |

1.0 ft./sec. (typical) (0.3 m/s) |

Accuracy: |

+/- 0.25% of distance reading |

Repeatability: |

0.1 ft. (30 mm) |

Resolution: |

1/100 ft. (0.12 inch; 3mm) |

Mounting: |

Freeze-Resistant "K" flange, 8" dia. |

Conduit Entry: |

Two 3/4" NPT |

Cable: |

1/16" nylon-jacketed (270lb/123kg tensile strength) |

Output Signal: |

|

Standard "Smart": |

RS-485 half-duplex, isolated, proprietary protocol |

Pulse: |

Discontinued |

Analog: |

4-20 mA, reversible to 20- 4mA, isolated; |

Input Signal: |

|

Sound (Pulse, Analog) |

Vhi - 98-265VAC/VDC, 9.5K ohm input, isolated |

Lockout (All) |

Vhi - 98-265VAC/VDC, 9.5K ohm input, isolated |

Wiring Distance("smart"): |

3,280 ft (1,000 m) max. @ 9600 baud, 26 AWG |

Address Determination ("smart"): |

1-16 (switch selectable) |

Internal Display (Analog): |

2 lines, 8 characters per line, LCD |

| Enclosure: | Cast aluminum with powder coat finish |

SMU Weight (Approx.): |

42 lbs. (19.1 kg) |

Plumb Bob Weight (Approx.): |

2 lbs. (0.9 kg) |

| Ship Weight (Approx.): | 45 lbs. (20.4 kg) - Includes SMU, plumb bob, cable & carton |

| Ship Carton Dimensions (H x W x L): |

16 x 15 x 34 inches (406 X 381 X 864 mm) - Includes SMU, plumb bob & cable |

Air Purge Connection: |

1/4" NPT |

Enclosure Rating: |

NEMA 4X / Enclosure Type 4X; IP66 |

Listings / Approvals: |

CSA(US/C): Ordinary Locations; |

HMI2 Operator Interface Control Console |

|

Power Requirements: |

100 - 240VAC, 50/60 Hz |

Power Consumption: |

6 VA max |

Operating Temperature: |

-4° to +131°F (-20° to +55°C) |

Sensor Communication: |

RS-485 half-duplex, non-isolated, proprietary protocol |

Channels: |

Two 16-channel networks (32 channels total) |

Display: |

2-lines by 20-characters per

line |

Keypad: |

20 keys |

Indicators: |

8 LEDs (function, relay, error status) |

Enclosure: |

Painted Aluminum |

Approvals: |

CE Mark |

AUXILIARY OUTPUT ENCLOSURE (AOE) |

|

Power Requirements: |

115 VAC or 230 VAC, 50/60 Hz |

Power Consumption: |

25 VA max |

Operating Temperature: |

-4° to +131°F (-20° to +55°C) |

Communication: |

RS-485 half-duplex, isolated, proprietary protocol |

Analog Outputs: |

4-20mA, 16 max, 4 per card, non-isolated, 500 ohm max loop resistance, 10 bit resolution, zero/span set via HMI/SiloTrack™ |

Relay Outputs: |

SPST, 5A @ 250 VAC, 32 max, 8 per card, visual LED per relay, assignment and action set via HMI/SiloTrack™ |

Enclosure: |

Painted aluminum |

Overall Dimensions |

2-Card: 11.02 x 9.05 x 4.33 in |

Enclosure Rating: |

NEMA 4; IP66 |

Approvals: |

CE Mark |

Teflon® is a registered trademark

of Dupont Chemical Co.

Windows® is a registered trademarks of

the Microsoft Corporation

RSView® is a registered trademark of Rockwell Automation

Wonderware® is a registered trademark of Wonderware Corporation

Intellution® is a registered trademark of Intellution,

Inc.

Cimplicity® is a registered trademark of General Electric

Company

Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

ModbusTM is a trademark of Schneider Electric / Modicon

Android, Google Play, and the Google Play logo are trademarks of Google Inc.

Need some more information?...Click on the button.

Need some more information?...Click on the button.