| |

PRODUCTS

|

|

|

|

|

|

|

TILT LEVEL SWITCHES - TC-1 and TC-3

|

|

|

Low

Cost, High Level Detection |

|

No

Calibration |

|

Minimal

Maintenance |

|

|

|

|

|

|

Monitor’s

line of tilt bin level switches are economical, trouble-free

point level controls available for detection of dry bulk materials.

The units can be used as high level indicators to eliminate

bin overflow or to control levels in open piles. In addition,

the tilt switches are useful in determining over or under-load

on conveyor belts. The simple yet efficient internal construction

(one moving part) provides indication when unit is tilted

at a 17° angle throughout the complete 360° of axial

arc. Each tilt switch includes a threaded bore for attaching

extension actuators which can increase sensing repeatability

and protect the tilt switch from direct contact with coarse

material. Monitor offers two different models of tilt switches,

each suited to satisfy different application requirements.

|

|

Principle of Operation |

|

A tilt

switch provides indication by detecting the angular position

of the tilt switch enclosure. Typically the unit is suspended

above the material to be sensed. Internally, a steel ball

centers itself over a switch resulting in switch actuation.

As rising material contacts the tilt switch (or the extension

actuator) the enclosure begins to tilt. When the enclosure

body is tilted at 17°, the steel ball rolls off center,

deactivating the switch. As material falls away from the

switch enclosure body (or the extension actuator) and the

unit becomes upright, the ball returns to its original centered

position, once again causing switch actuation. The change

in the internal switch status is user accessible for signaling

alarms, lights, or interfacing with a PLC.

|

|

Applications |

|

|

|

Monitor’s

tilt switches can be used in a variety of applications and

with many different types of materials. The TC-3 can be

used with materials 15-60 lb/ft³ (240-960 kg/m³ ), while

the TC-1 can be used with materials >45 lb/ft³ (>720

kg/m³ ).

Typical Applications include, but

are not limited to: |

Feed |

Calcium Dust |

Pellets |

Wood |

Limestone |

Metals |

Regrind |

Rocks |

Clays |

Resin |

Rubber |

Malt |

Silica Sand |

Pre-mix |

|

|

|

Features |

|

|

Passive

switch for activating loads up to 250 VAC |

|

Cast

iron or cast aluminum construction |

|

Easy

installation |

|

Adjustable

measurement height |

|

Ball-float actuators available - see Optional Accessories section |

|

|

Available Configurations |

|

TC-3 - Monitor’s model TC-3 is a light-duty tilt switch

constructed from cast aluminum. It is ideally suited

for applications where relatively light weight, moderately

sized materials are handled (i.e. 15-60lb/ft³ ; 240-960kg/m³

or particle sizes less than 2in; 50mm). Typical application

materials include feed, plastic pellets and pet food. (Extension actuators are optional. See Optional Accessories Section.) TC-3 - Monitor’s model TC-3 is a light-duty tilt switch

constructed from cast aluminum. It is ideally suited

for applications where relatively light weight, moderately

sized materials are handled (i.e. 15-60lb/ft³ ; 240-960kg/m³

or particle sizes less than 2in; 50mm). Typical application

materials include feed, plastic pellets and pet food. (Extension actuators are optional. See Optional Accessories Section.)

|

TC-1 - Monitor’s model TC-1 is a heavy-duty, weather-proof

tilt switch constructed from cast iron. It is ideally

suited for applications where heavy coarse materials

are handled (i.e. >45lb/ft³ ; >720kg/m³ or

particle sizes exceeding 2in; 50mm). Typical application

materials include coal, ore, rock, aggregate, and sand. TC-1 - Monitor’s model TC-1 is a heavy-duty, weather-proof

tilt switch constructed from cast iron. It is ideally

suited for applications where heavy coarse materials

are handled (i.e. >45lb/ft³ ; >720kg/m³ or

particle sizes exceeding 2in; 50mm). Typical application

materials include coal, ore, rock, aggregate, and sand.

|

|

|

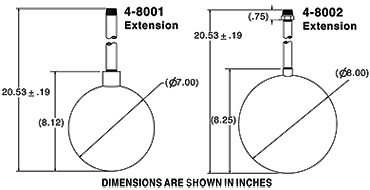

Optional

Accessories (TC-3) |

|

#4-8001 Extension actuator for TC-3, 20” overall extension length, stainless steel extension and 7” diameter ball float (assembly required; does not include TC-3)

#4-8002 Extension actuator for TC-3, 20” overall extension length, 8” dia. polypropylene ball float with galvanized steel extension(assembly required; does not include TC-3)

|

|

Specifications |

|

Model

TC-3: |

Power

Requirements: |

None |

Output: |

SPDT,

10A @ 250 VAC max |

Sensitivity: |

17° from

vertical axis |

Enclosure: |

cast

aluminum, unpainted |

Enclosure

Protection: |

NEMA

4, IP56 |

Mounting

Connection: |

Eyebolt,

3/4" (19mm) I.D. |

Wire

Entry: |

3/8" NPT

cord connector, cord diameter 0.25 to 0.38in

(6.4 to 9.6mm) |

Op.

Temp.: |

-40° to

175°F (-40° to 79° C) |

Weight: |

3

lbs. (1.35 kg) |

Approvals: |

CE marking (Ordinary

Locations Only) |

Model TC-1: |

Power Requirements: |

None |

Output: |

SPDT, 15A @ 250 VAC max |

Sensitivity: |

17° from vertical axis |

Enclosure: |

cast iron, painted beige |

Enclosure Protection: |

NEMA 4, IP56 |

Mounting Connection: |

Eyebolt, 1-3/32" (27.7mm) I.D. |

Wire Entry: |

1/2" NPT cord connector, cord diameter

0.25 to 0.38in (6.4 to 9.6mm) |

Op. Temp.: |

-40° to 250°F (-40° to 121° C) |

Weight: |

24 lbs. (11.25 kg) |

Approvals: |

CE Marking |

|

|

|

Warranty |

|

Monitor

Technologies warrants each tilt switch it manufactures to

be free from defects in material and workmanship under normal

use and service within two (2) years from the date of purchase.

The purchaser must notify Monitor of any defects within

the warranty period, return the product intact, and prepay

transportation charges. The obligation of Monitor Technologies

LLC under this warranty is limited to repair or replacement

at its factory. This warranty does not apply to any product

which is repaired or altered outside of Monitor Technologies'

factory, or which has been subject to misuse, negligence,

accident, incorrect wiring by others, or improper installation.

|

|

Part Numbers / Product Configurations |

|

Part

# > Product Configuration

4-3103 > TC-1 tilt switch, standard unit with heavy duty cast iron housing

4-8131 > TC-3 tilt switch, medium duty, cast aluminum housing |

|

Last Rev. March 16, 2015

|

|

|

|

|

|

|

|

|

QuantiMassTM

Mass Flow Measurement Systems |

The QuantiMass in-line mass flow sensor measures the flow of quantities in pneumatic conveying & free-falling processes. The sensor is based on the latest Microwave Doppler Effect technology and provides fast, in-line / on-line measuring without the use of weight scales.

The sturdy, non-intrusive design of the sensor minimizes maintenance. In addition, the compact size of the sensor makes for easy installation into existing processes. Suitable for powders, dust, pellets, and granular up to 0.75 inch (2cm).

Versions:

Ultra Series-Includes controller

PRO Series-Includes transmitter

A practical application for the QuantiMass would be to monitor material flow rates to verify blending mixture ratios.

Principle of Operation:

The QuantiMass Mass Flow Measurement Sensor / Meter is designed with the latest microwave technology and is used to continuously quantify the flow of powders & solids being conveyed in metallic pipes. The QuantiMass is based on technology that has been developed and proven over several years. The measurement process of the sensor is centered on the Doppler effect. The mass flow-rate is determined by evaluating the frequency and amplitude changes during the measurement process. Particles at rest, such as deposits, do not influence the measurement. All powders, dust, pellets and granules can be measured reproducibly, up to the size of 0.75 inch (2cm). The QuantiMass sensor is suitable for continuous in-line / on-line measurements in pneumatic conveying or in free-fall pipelines.

Click

here for more information on the QuantiMass

or

contact Monitor Technologies LLC at

Tel.: 800-601-6319 in the USA and

Tel.: 630-365-9403

worldwide.

|

|

|

|

|

|

|

|

|

|

|

|

|

|